Fingernails

FICEP's RAZ sets the record for the highest level ever of productivity on a standalone thermal cutting machine

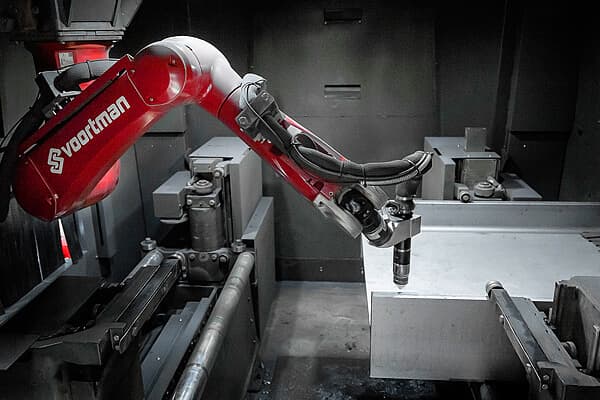

The V808 roller feed measurement and clamping system locks profiles in exact position and maintains alignment throughout processing. This fully automatic measuring roller feed system is the fastest positioning system as it does not require a pusher or gripper to return home before loading the next piece saving hours each week. Voortman�s roller feed system can operate with full automation within a standard range of profile processing when using Voortman�s automated in-feed cross transports, with enough stability and support to properly position and process beams up to 15.000 kg (33,000 lbs).